Meet the Knife-Maker

BLOK ARTICLE WRITTEN BY:

Meet The Knife-Maker

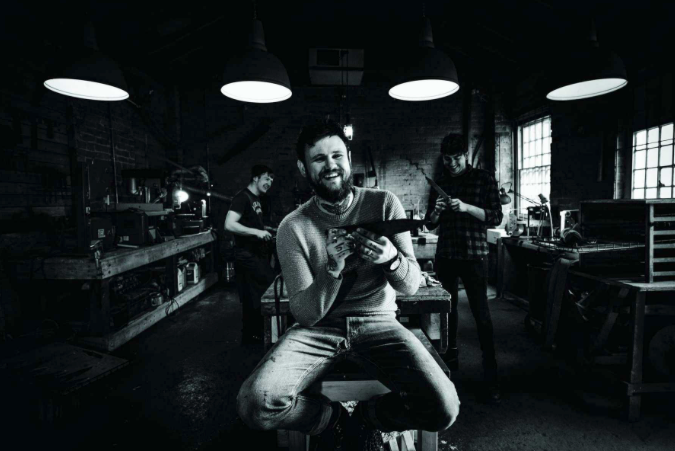

Ben Edmonds first tried forging knives after seeing a YouTube video. Now he makes a living from Blok Knives, crafting quality blades by hand.

I've always been into making stuff. I worked as a graphic and web designer for about 12 years, and I suppose fixing things and creating something tangible was a reaction to sitting behind a desk, looking at a screen all day. In the past, I've messed around with cars and modified furniture, but then about three years ago, I watched a video about making knives on YouTube and decided to give it a go.

I bought a few hand files and some cheap metal from eBay then spent a few hours at my kitchen table making a knife. I loved the process, and with each new knife I made, I wanted to modify the next one to make improvements.

There was never any intention of selling my knives, but then the chef in my local pub asked me to sharpen his Japanese knives for him. Another guy in the pub overheard this and asked to see what I'd been making, and insisted on buying one from me. After some bartering, he walked away with a 20cm chef's knife. It made me realise that I had something good, so I decided to throw together a website – which I'd been doing all the time in my old job – and worked on a logo.

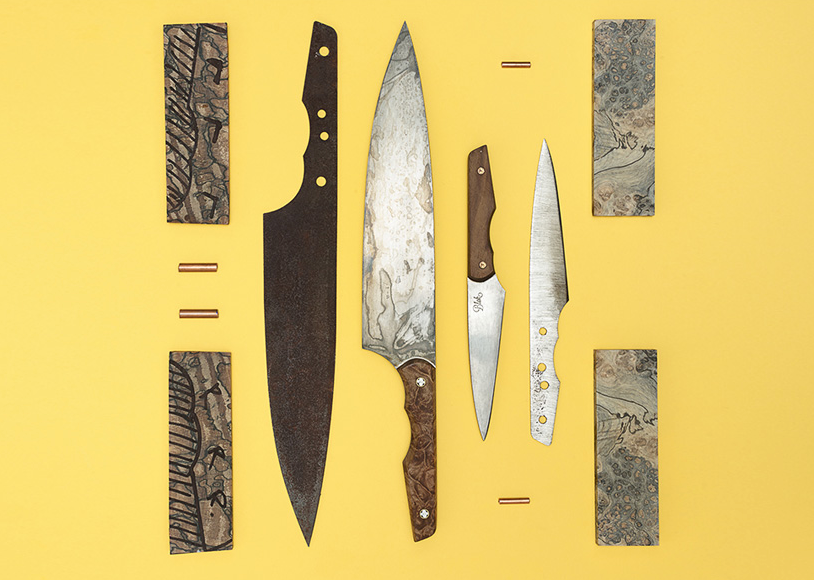

Being a maker of anything is about weighing up how much time it takes you with the quality of product you want, and where there can be compromises. With knives, the handle juncture, the weight and balance are all really important, but ultimately the blade has to be a good mix of extra-sharpness for fine chopping, and the strength to handle larger jobs, too. I could use more machinery to make them faster, but to me, the knives have to feel homemade. It took me about a year to get the chef's knife how I wanted it, although each one is a one-off, different and perfect in its own way.

It takes about a day to make each knife. Bigger brands have so many different styles, but I really believe that you only need one, or two at most. I make an 20cm chef's knife and a 10cm paring knife.

I stick with one metal, carbon steel. It's an old-fashioned style to use, but it holds a really good edge. At the moment, I'm making my handles out of wood; I try to keep it as simple as possible, but customers can choose different burrs to make their knife unique. I enjoy commission projects for different styles, such as steak or boning knives, but at home we just use one of my chef's knives.

I'm never going to get rich from doing this; but if I can pay my mortgage and keep my family, then it's happy days. I've never advertised, so it's just grown at its own pace, and I've been lucky enough to make knives for interesting folk. It can be pretty scary at times, but I love my job so much that I wouldn't change it for the world.

To view the original article by The Guardian, click here.